Sustainable technology supplier Nextek and manufacturer of flexible packaging Coveris have formed a partnership to convert post-consumer polyolefin (PE & PP) packaging waste into high-quality food-grade recycled resins and films.

The COtooClean process, a Nextek technology, solves a problem in the recycling of PE and PP films, which are difficult to decontaminate, said Coveris. This is achieved as COtooClean uses a waterless cleaning and decontamination process to produce food-grade recycled materials from post-consumer plastic film.

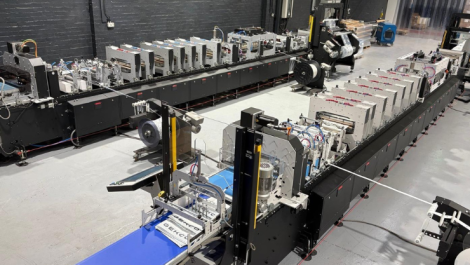

As part of the partnership between Nextek and Coveris, a demonstration plant is now being developed in the UK. The plant will implement the COtooClean technology at industrial scale, with trials planned to collect the data needed to meet regulatory requirements, along with the opportunity to demonstrate the technology to industry. The goal is to make this pioneering process available globally, helping tackle one of the toughest recycling challenges, explained Coveris.

Edward Kosior, CEO and founder of Nextek, believes COtooClean has the potential to transform plastic film recycling. Described by Mr Kosior as the next big step, the partnership with Coveris will demonstrate this technology at scale which will work toward a circular economy for plastic films.

Christian Kolarik, CEO of Coveris, concluded: “We’re really a frontrunner in this topic and we are thrilled to collaborate with Nextek on this project – a breakthrough in food-grade mechanical recycling. Sustainability is at the heart of Coveris’ ‘No Waste’ strategy, and this partnership is another milestone in ending plastic waste. Together with our ReCover recycling entity and our collaboration with Interzero, we are taking bold steps towards turning waste back into a valuable resource.”