Print finishing equipment manufacturer A B Graphic International (ABG) has reported a “significant” increase in retrofit sales, with demand rising by 239%. The company completed over 170 retrofit installations in 2024, reflecting a growing trend among customers looking to extend the capabilities of their existing equipment.

ABG’s machines are designed with modularity in mind, allowing customers to upgrade their systems as their needs evolve. This flexibility enables businesses to enhance production capacity, improve efficiency, or integrate new technologies without investing in entirely new machinery.

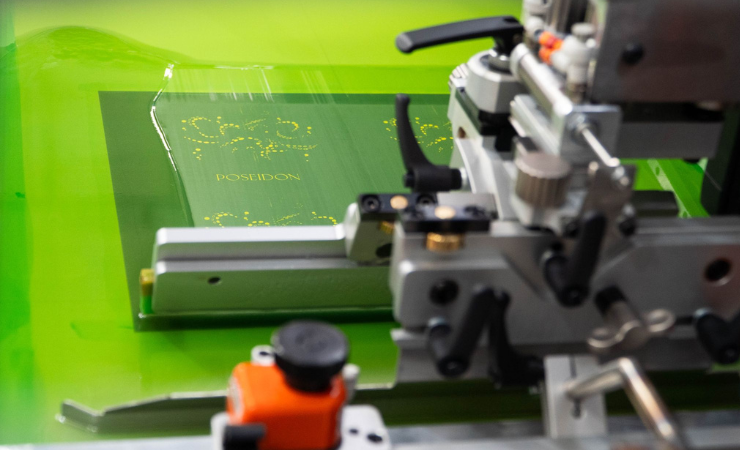

Among ABG’s retrofits is the flat bed foil module, available in 25-tonne and 50-tonne Big Foot units, which can be used for foiling, embossing, or both. These upgrades are particularly popular in the embellishment sector, where premium finishing is essential, said the company. The high-speed screen module is another installed enhancement, offering advanced varnish effects that add both visual and tactile appeal to labels and packaging.

Another upgrade is the re-register lamination retrofit. This enables the production of multi-layered labels, such as peel-and-reveal products, by laminating a pre-printed web onto the main web in perfect register. In addition, ABG’s software-based upgrade, ABG Connect, is designed to streamline automation in the labels and packaging market, allowing for automatic job set-up and changeover with minimal operator intervention.

Peter Redmond, ABG’s director of service, commented: “Demand for ABG’s retrofit offering has risen over the last few years, allowing our customers to adapt their machinery as their business grows and changes. We’re proud to have such a dedicated team of engineers, trusted by our customers to enhance their production capabilities.”